An international team of researchers led by Penn State engineers are exploring the development of stretchable self-powered biosensors that could one day lead to wearable devices that do not need to be recharged, or even sensors that are powered by the very bodily process they are designed to monitor. Image: Penn State

Self-powered biosensors may open up new paths to medical tracking, treatments

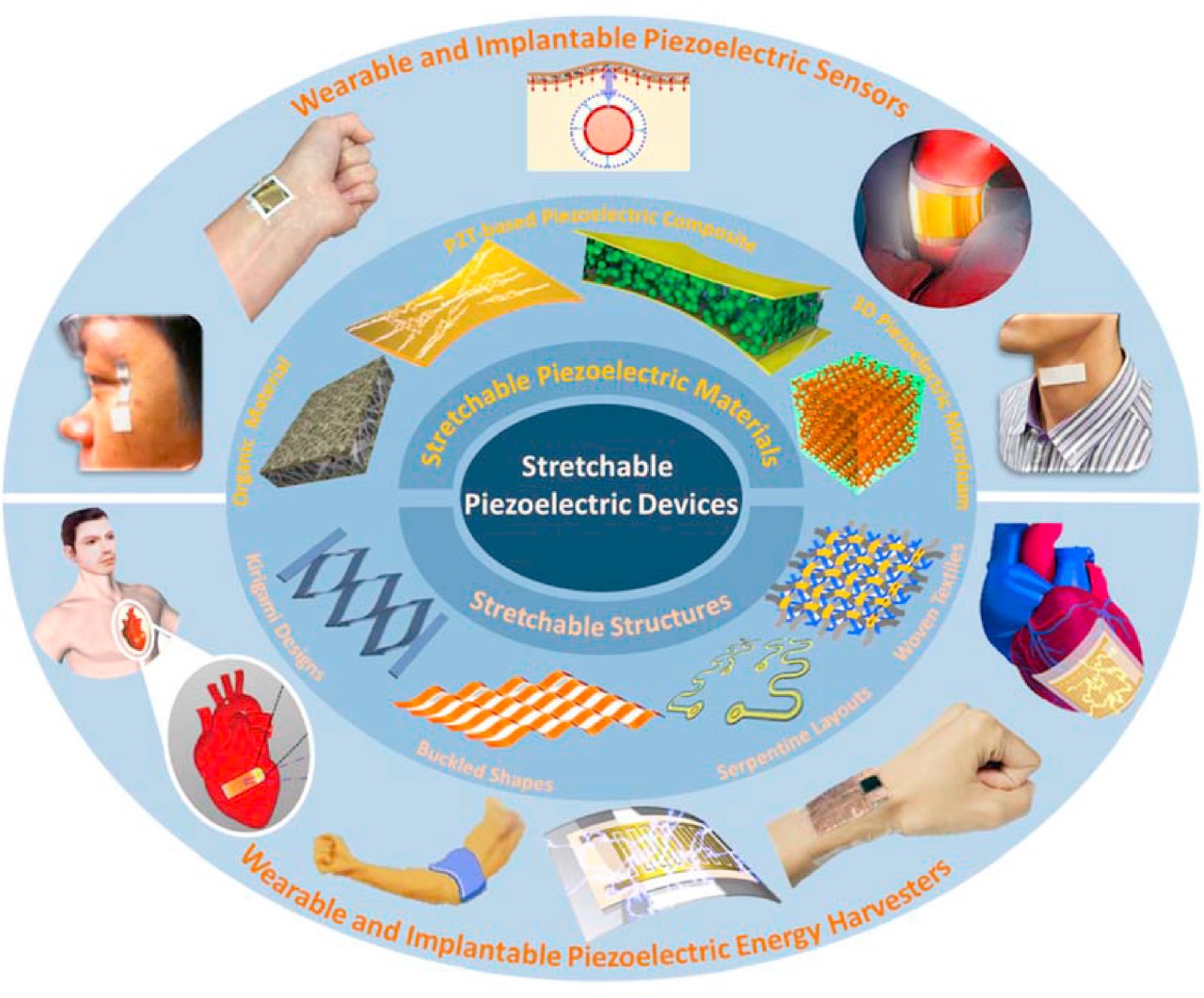

Posted on September 10, 2020UNIVERSITY PARK, Pa. — Wearable and implantable devices are currently used for a variety of functions, including health tracking and monitoring. However, supplying energy usually requires cumbersome batteries and downtime due to recharging. Now, an international team of researchers suggests that advances in materials and electronic design may be able to convert biomechanical energy into electric energy, paving the way for devices that can be worn and implanted but do not require constant recharging, according to Larry Cheng, Dorothy Quiggle Career Development Professor in the Department of Engineering Science and Mechanics and an affiliate of the Institute for Computational and Data Sciences.

“In this particular review, we are looking at possible energy supply without the need for batteries and other components, so it’s of particular interest to create these energy harvesters for self-powered devices, or ones that could also be used to charge up a battery,” said Cheng.

Cheng said the team reviewed the field from two perspectives: creating devices that can harvest energy, and developing sensors that can power themselves. He said that an energy harvester can create energy to power other devices, while self-powered sensors can provide their own energy to serve as stand-alone devices. Cheng added that, in some cases, the motion that generates the energy for the sensor may also be the data that the sensor is trying to collect.

“It can serve as a sensor directly because it can harvest energy, so it can provide the capability to monitor the motion — for example the heartbeat — or whatever the sensor is applied to, and then it can transmit that information from the environment, or from the body, so it can be analyzed,” said Cheng.

These sensors could lead to more precise healthcare and remote health opportunities, according to the researchers, who report their findings in a review article in Biosensors and Bioelectronics, currently online.

The researchers said that stretchable piezoelectric materials — which are solid substances that can accumulate electrical charges — are critical to this development. Because human tissues are soft and constantly changing shape, the materials need to be able to flex and stretch as these tissues flex and move.

“These devices could include wearables on the skin surface,” said Cheng. “For these types of devices, we can capture information from the skin surface in the form of blood flow, heartbeat, respiration rate and similar movements that create vibrations.”

With new materials, the flexing motion of moving muscles, which typically are a hindrance for often-rigid wearable devices, could actually help create the energy that would then be captured and used as power by these biosensors.

However, according to the researchers, biosensors may not just be relegated to the skin surface, but could one day be implanted in the body. According to Cheng, advances in material design and development in the last decade have helped researchers develop piezoelectric materials that are flexible and rugged enough that they can withstand the environment inside the body, yet are so sensitive and efficient that they can capture and convert very minute motions, such as heartbeats and respiration.

“That’s the amazing thing about these devices, people think that these types of motion are very minimal and don’t think about harvesting this energy,” said Cheng. “It was in the past decade or two when people began to see the possibilities to generate rather large signals from these movements through the high-efficiency circuits and also to use the high-efficiency rectifying circuit, which would consume a lot of energy if it isn’t designed correctly.”

The team is also eyeing creating sensors that can perform double duty — they can harvest energy from the very bodily processes they have been designed to monitor. For example, a sensor could harvest energy from heartbeats and also transfer the information on the heart to doctors who are monitoring a patient’s cardiovascular condition.

Because computational resources are needed to create accurate models for achieving these high-performance devices, Cheng expects that advanced computational systems, such as the ones provided by the Roar supercomputer, will be needed for future work.

Yabin Liao, assistant professor of engineering, mechanical engineering technology, Penn State, added that analyzing past approaches for designing stretchable energy harvesters and self-powered sensors can help researchers address current-day design challenges.

“Accurate models provide a useful platform for analytical and numerical analysis of system behaviors, and allows design optimization of system parameters,” said Liao. “We summarized the working principle and representative models of flexible piezoelectric sensors and energy harvesters, and discussed their unique characteristics as compared to conventional devices. We also provided an important perspective on the connection between these and conventional models, yielding a deeper understanding of their behavior at the system level.”

Cheng and Liao also worked with Honglei Zhou, visiting doctoral student in engineering science and mechanics at Penn State and doctoral student at Northwestern Polytechnical University; Yue Zhang, visiting undergraduate student in engineering science and mechanics at Fudan University; Ye Qiu, visiting doctoral student in engineering science and mechanics at Zhejiang University of Technology; Huaping Wu, professor at Key Laboratory of E&M, Zhejiang University of Technology; and Weiyang Qin and Qingmin Yu, both professors in the department of engineering mechanics, school of mechanics, civil engineering and architecture, at Northwestern Polytechnical University.